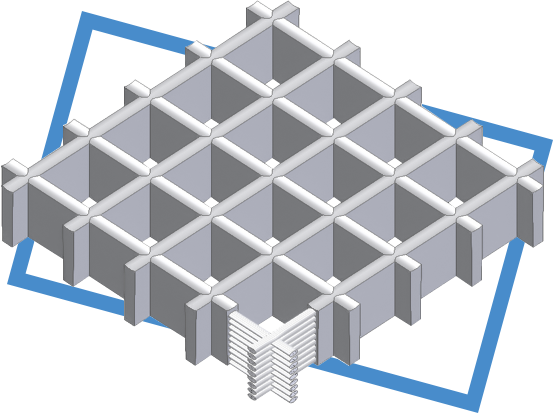

GRP gratings

FAQ about GRP gratings

What is fiberglass?

Fiberglass is a material commonly used in construction and the production of various products. It consists of thin threads or fibers made of glass, which can be woven or combined to form a strong and lightweight material.

Fiberglass has many applications, including in the manufacturing of boat hulls, car bodies, aircraft components, and in the construction industry for reinforcing concrete and other materials. It is known for its strength, rigidity, and resistance to corrosion, making it a popular choice in many technical and industrial applications — including GRP gratings.

What is isophtal?

Isophthalic polyester resin is a mid-range resin that sits between standard ortho-polyester and the more expensive vinyl ester. It offers better chemical resistance and higher temperature tolerance than ortho-polyester, while still being more affordable than vinyl ester.

Isophthal-based GRP gratings are typically used in environments with moderate chemical, saltwater, or moisture exposure — such as in the food industry, offshore installations, and water treatment facilities. Because it bonds well with glass fibers, it also provides longer service life in demanding conditions.

You could say that “isophthal” in GRP gratings is somewhat like “stainless steel” in metal structures — it represents a certain level of quality and resistance.

Is a GRP grating as strong as a steel grating?

GRP gratings and steel gratings are made from different materials, and their strength depends on various factors such as design, thickness, and application. Generally, steel gratings are known for their high strength and load-bearing capacity, making them ideal for areas exposed to heavy traffic or loads — such as industrial floors, walkways, and drainage covers.

GRP gratings, on the other hand, are typically lighter and are often used in environments where corrosion is a concern, as fiberglass is resistant to rust and chemical degradation. They are well-suited for use in coastal areas, chemical plants, or other corrosive environments.

Which type of grating is “stronger” depends on the specific application. Steel gratings usually offer higher load-bearing capacity, while GRP gratings are more advantageous in corrosive or moisture-prone settings. The key is to choose the type of grating that best matches the project’s load and environmental requirements.

Is the load-bearing direction as important for a GRP grating as it is for a steel grating?

No, the load-bearing direction is generally not as critical for a GRP grating as it is for a steel grating. Steel gratings are typically designed with a specific bearing direction, meaning they have greater load-bearing capacity in one direction due to their structural design and construction.

GRP gratings, however, are often more isotropic, meaning they have a more uniform strength and load-bearing capacity in multiple directions. This makes them more versatile, as they can be installed in different orientations without needing to consider the bearing direction to the same extent as with steel gratings.

Can I have my GRP grating produced in a specific colour?

Yes, we can manufacture our GRP gratings in almost any RAL colour, allowing them to be tailored to your specific needs. The colour is integrated directly during production, meaning the entire grating — both inside and out — has the same colour.

This ensures that you can safely cut the grating to size without worrying about colour differences inside the material.

Contact us for more information.

Back to GRP gratings