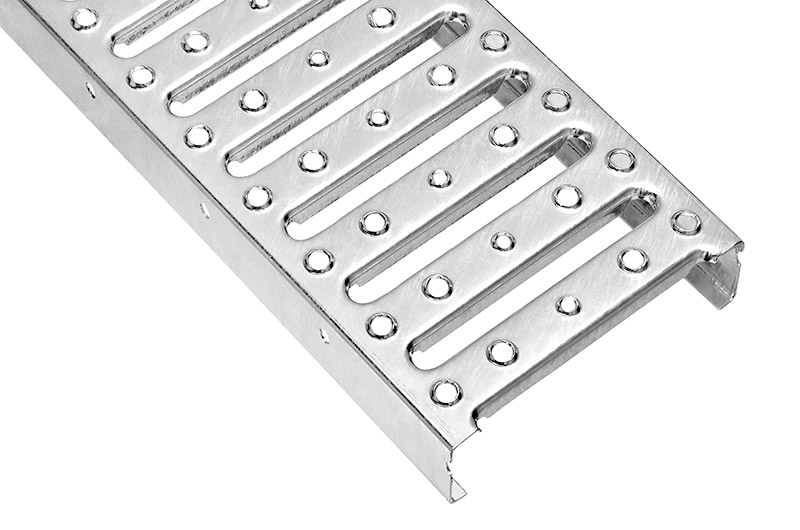

Perforated metal planks are C-profiled and edged perforated gratings, produced on a line consisting of CNC-controlled punching and rolling machines.

They are known for their simplicity, stability, and slip-resistant surfaces.

The planks can be manufactured from steel, stainless steel, or aluminium, and are available with various surface treatments such as hot-dip galvanizing according to DIN EN ISO 1461, or powder coating, among others.

Perforated metal planks and steps meet high slip-resistance requirements thanks to their specially designed surface profiles.

Applications

Perforated metal planks can be used in a wide range of applications, including:

-

Work platforms

-

Ramps

-

Facades

-

Workstations

-

Walkways and service paths

-

Large protective mats for work areas beneath conveyor systems

Advantages of perforated metal planks

-

High slip resistance: The serrated surface profile (BZ) provides excellent slip resistance, making them ideal for areas exposed to oil and grease.

Stability and safety: The perforated planks (BN-O) offer a stable and secure walking surface, enhancing workplace safety. With a hole diameter of 8 mm, they also allow effective drainage of liquids, particularly water.

High load-bearing capacity: Perforated metal planks can withstand heavy loads, reducing the need for expensive support structures and thereby lowering overall costs.

Easy installation and fast availability: These planks are easy to install, making them ideal for time-sensitive projects.

All our perforated metal planks and steps can be customized to meet specific requirements.

Contact us for more information and to discuss the options for your project. Our product specialists are always ready to help you find the best solution.

We also have a wide range of standard units in stock – you can find them here