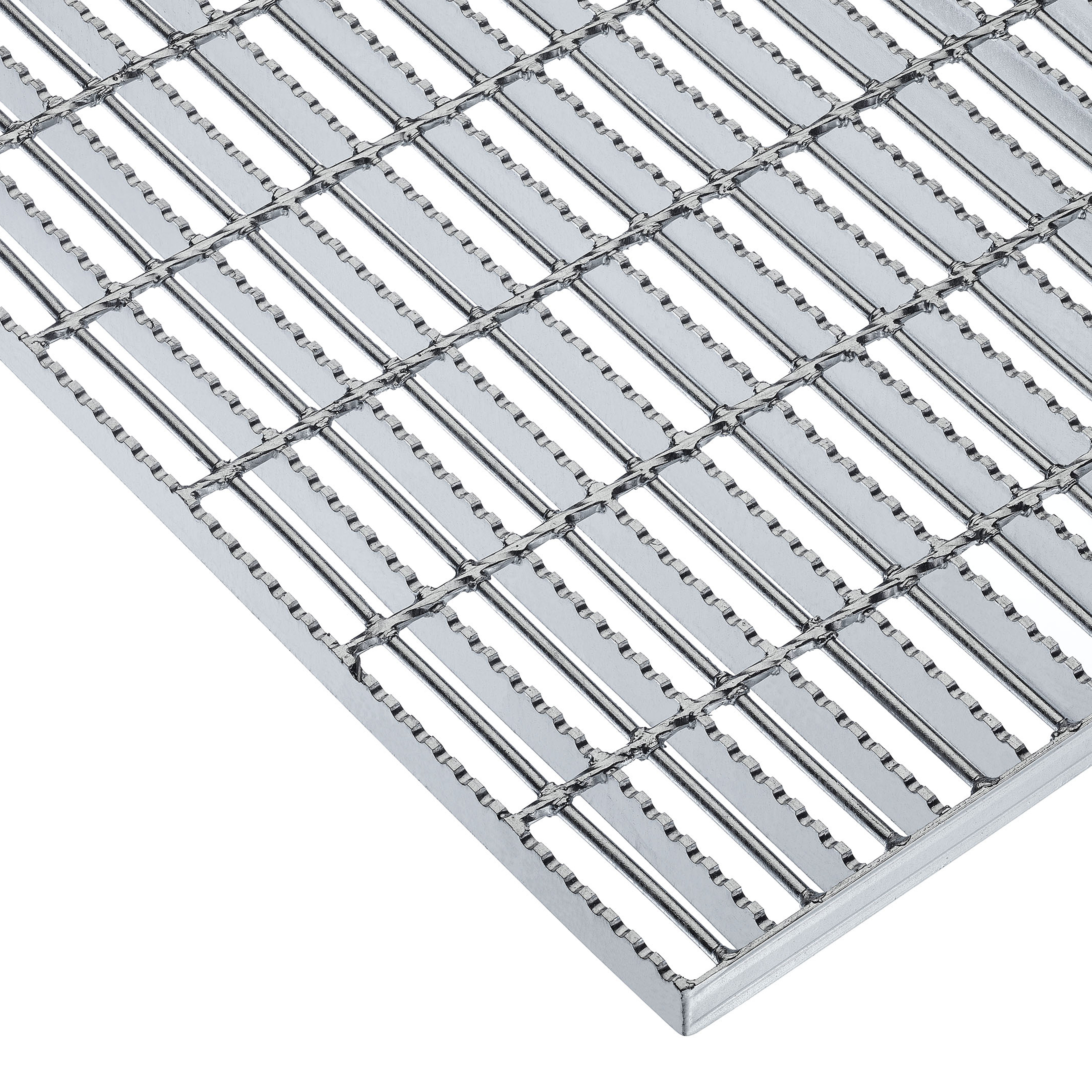

Advantages of offshore gratings

Offshore gratings are specially developed for use on drilling platforms in the oil and gas industry.

They are designed to withstand harsh environmental conditions while ensuring high stability and safety.

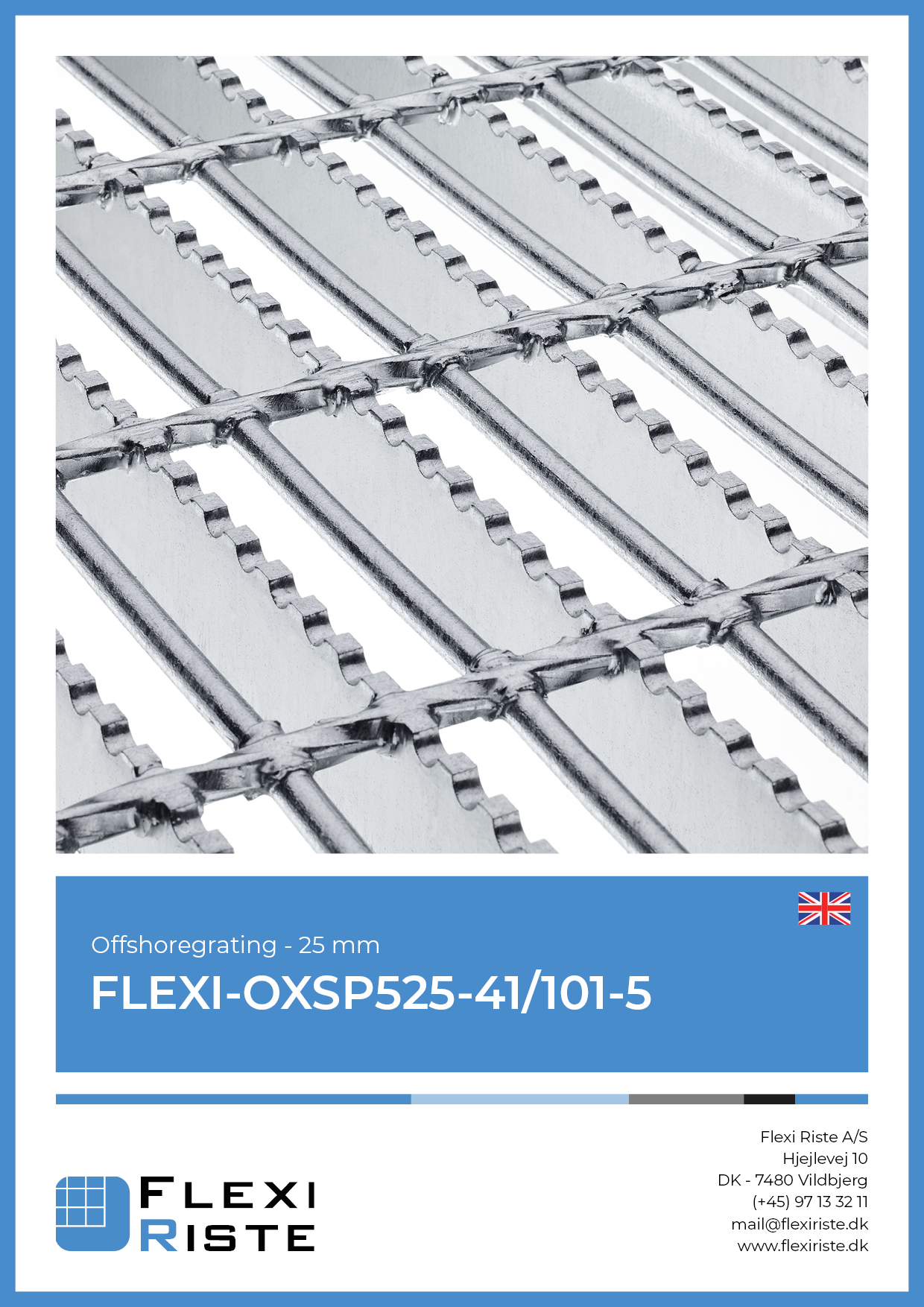

Construction

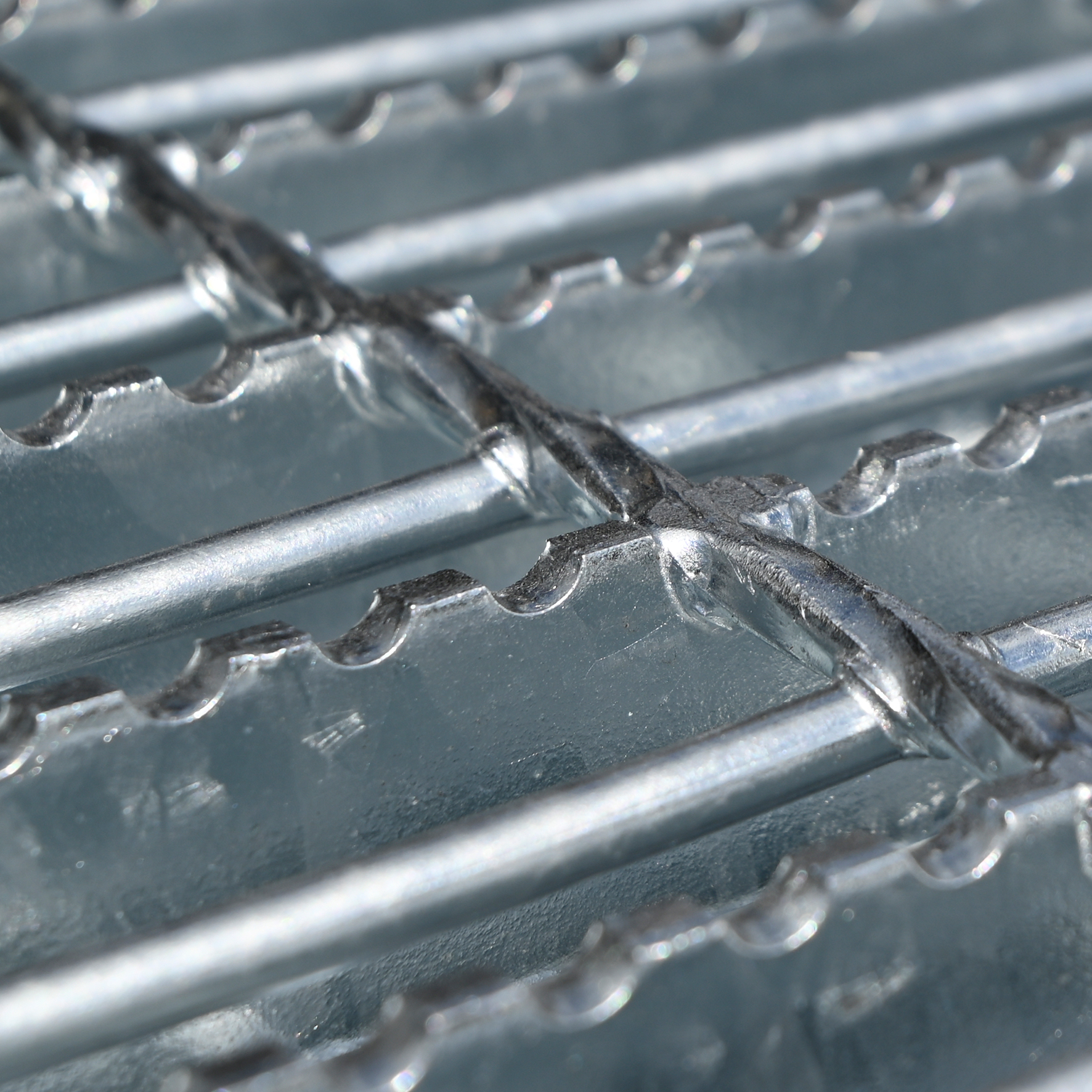

The twisted cross bars are forge-welded across the bearing bars to hold the grating structure together.

Round bars are welded in parallel on the underside of the serrated bearing bars, ensuring the grating meets the 15 mm ball proof requirement.

A hot-dip galvanized surface treatment protects the grating against corrosion in harsh and aggressive environments.

Serration

The serrated bearing bars ensure a minimum R12 slip resistance rating in accordance with BGR 181.

Even in the presence of oil, water, or ice, the offshore grating helps maintain personnel safety under changing and challenging conditions.

Material

- S355JR

Surface treatment

- Hot-dip galvanized according to DIN EN ISO 1461

Serration class

- R12

- 15 mm ball proof

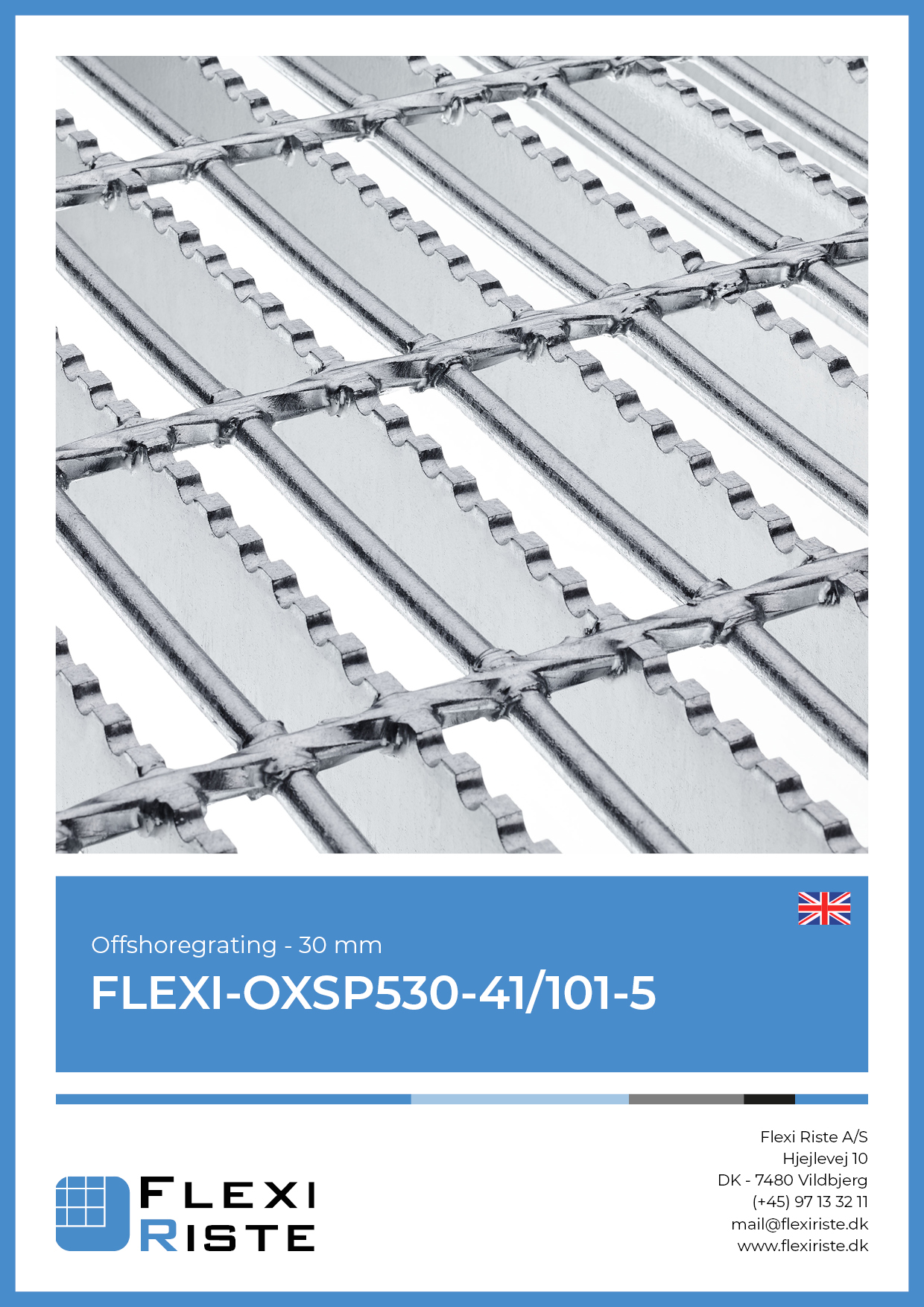

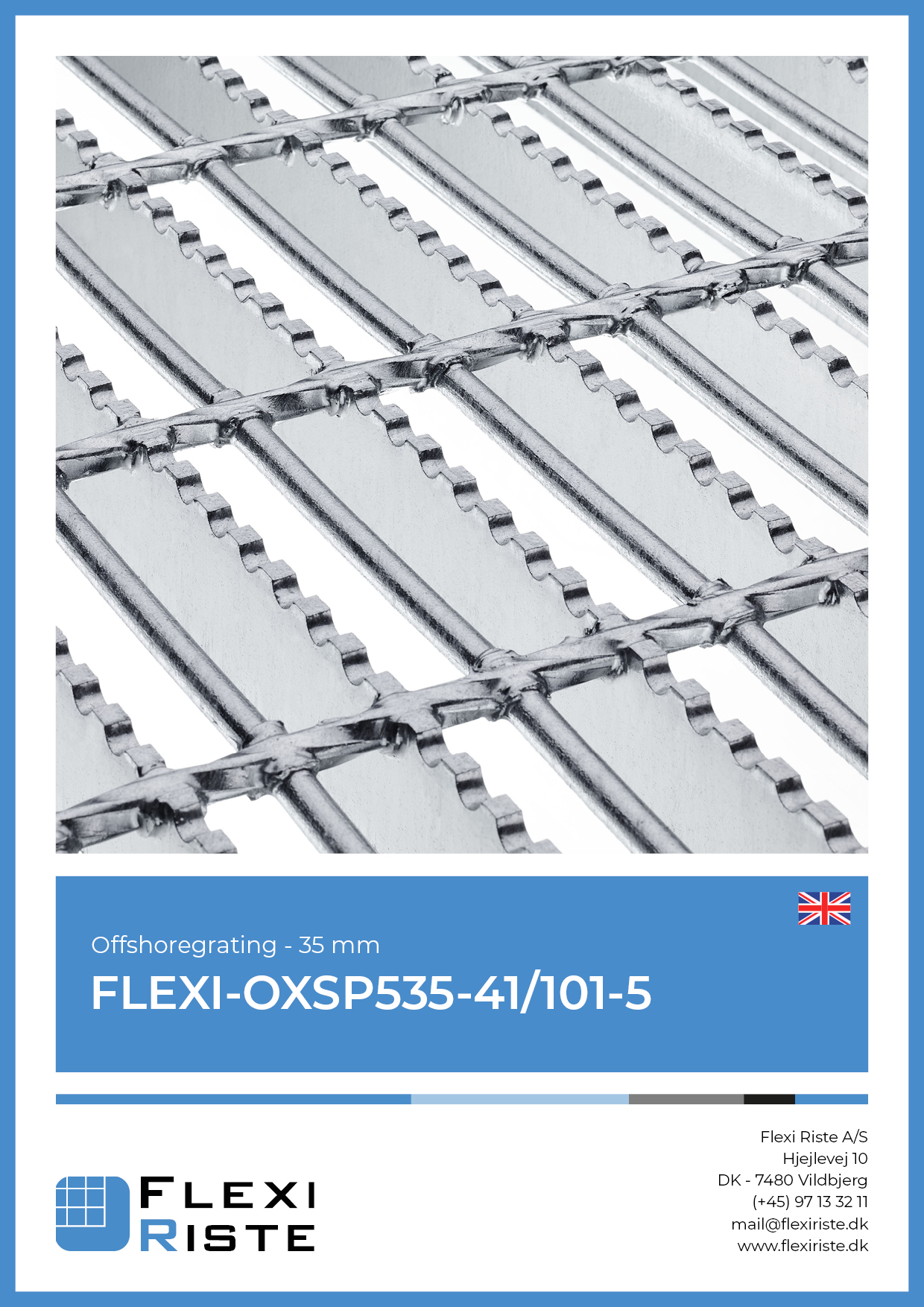

Bearing bar height

- 25 - 30 - 35 - 40 - 45 - 50 mm

Bearing bar thickness

- 3 - 5 mm

Bearing bar spacing (c/c)

- 41,46 mm

Cross bar (twisted bar)

- Ø8 mm

Round bar

- Ø7 mm

Cross bar spacing (c/c)

- 101,6 mm

Mesh size

- 41 x 101 mm

According to standards

- MOTS-31

- EN ISO 14122

Download our data sheets here

Offshore gratings can be custom-made to specific dimensions, but we also stock standard sizes