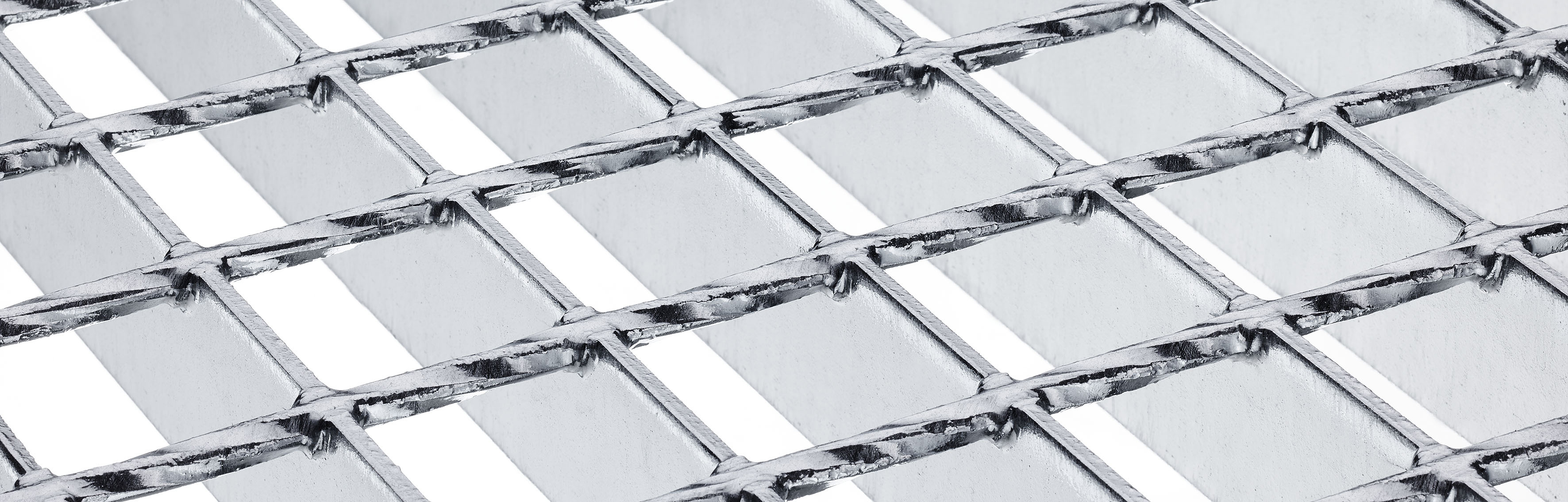

Decades of experience and the continuous development of modern, partly patented production methods have made our twisted bar gratings among the best-selling products in the grating industry.

FORGE WELDED GRATINGS: CONSTRUCTION

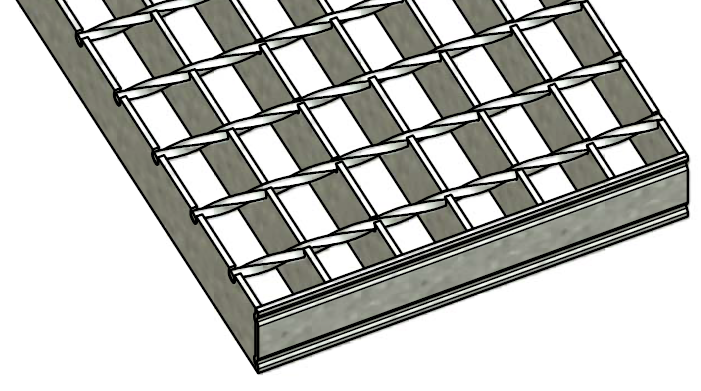

Twisted or round cross bars are pressed into the bearing bars in a single operation with a force exceeding 1000 kN, while being electrically forge-welded at the same time. This process creates a highly rigid and dimensionally stable grating. The production method is very efficient, which is why forge welded gratings – with few exceptions – are more cost-effective than pressure locked gratings. We also supply custom-made forge welded gratings when the project requires it.

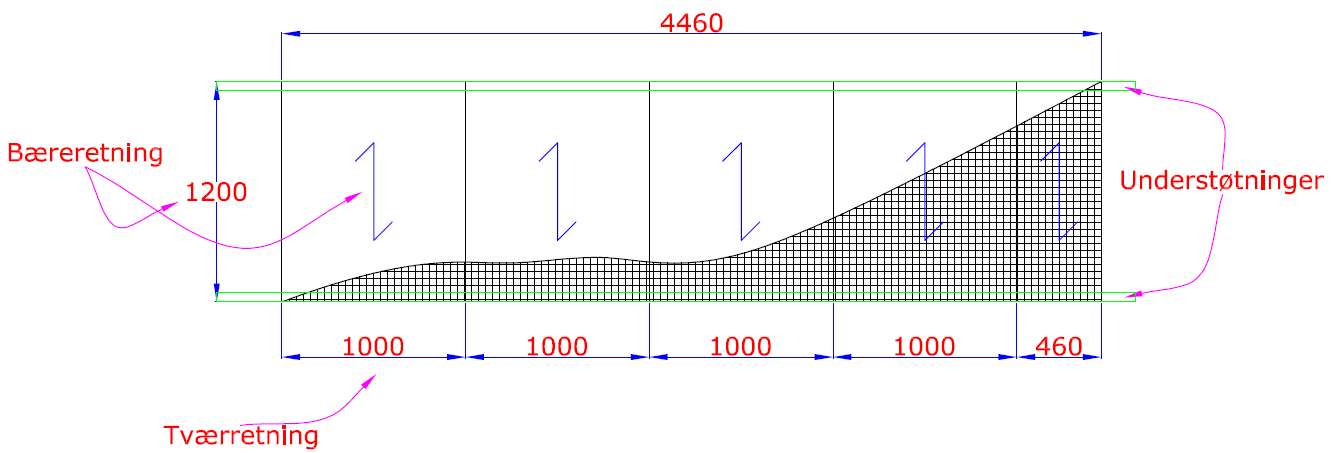

This type of grating is particularly advantageous for large surface areas or walkways, where multiple gratings can be installed with a transverse length of 1000 mm.

PROCESSING OF FORGE WELDED GRATINGS

The special construction of the forge welded grating makes this type of grating extremely resistant to twisting and cutting.

FORGE WELDED GRATINGS WITH EDGE FLAT BAR

Forge welded gratings are always supplied with an edge flat bar. In a specially developed production process, the edge bar is double-welded automatically to each bearing bar. The result is forge welded gratings of consistent high quality with clean edges and corners. In the direction of the bearing bars, the edge bar is flat. Heavy-duty gratings are equipped with a flat edge bar all around.